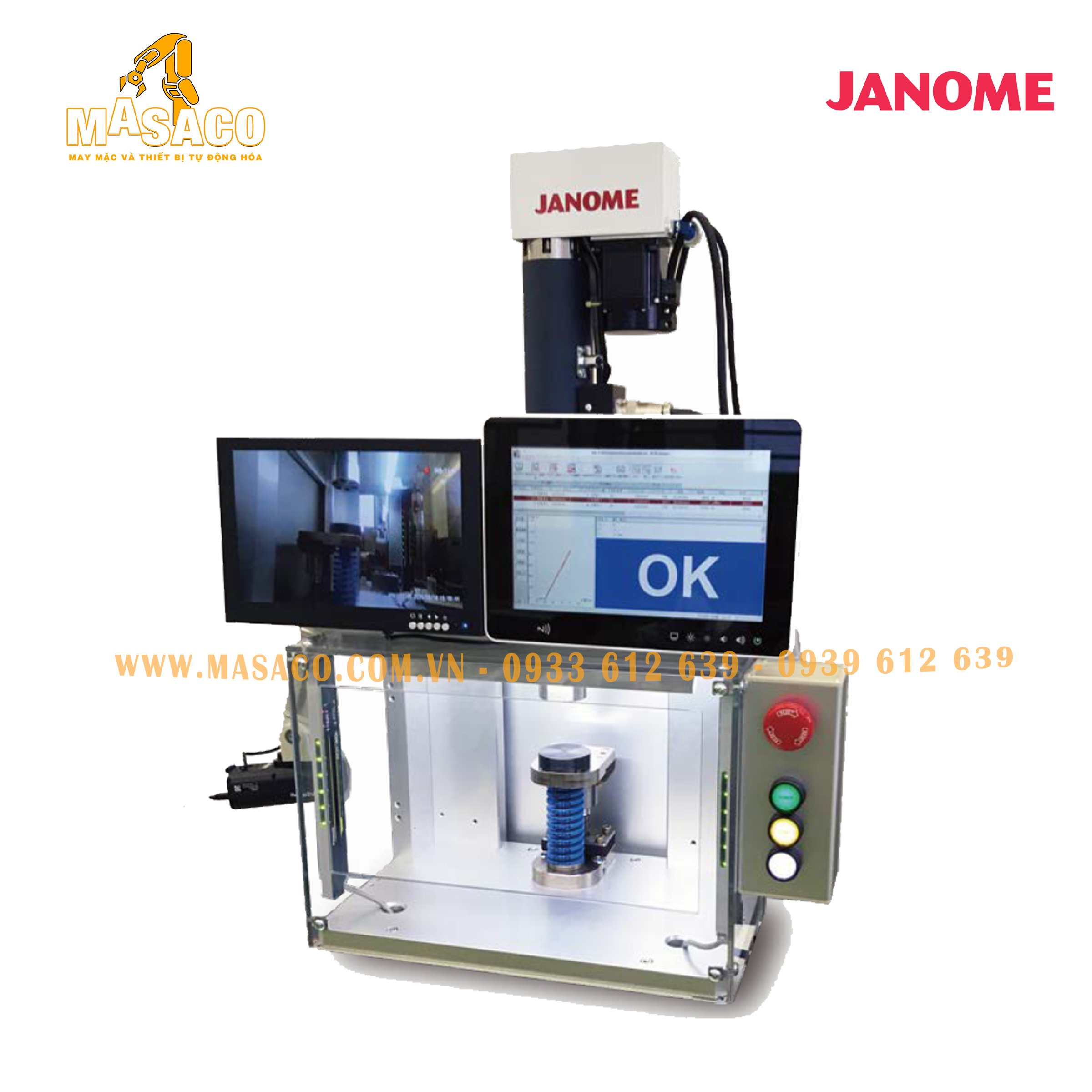

Stand-Alone Type (Flexible Model)

Designed to fit in any facility…

Choose the installation that’s best for you

TẢI FILE PDF: External Diagrams

TẢI FILE PDF: Product Catalogs

Features

Suitable for Both Inline and Cell Installation

Inline: easily install the C-frame press by itself to save space

Cell: connect the Switchbox for a manually operated all-in-one pressing system

Ethernet-based Traceability (loT)

DExport high-speed sampling data to a PC via the Ethernet.

0.25msec position and load value sampling interval is the fastest in the industry.

Multilingual Display Screen

Switch among 13 different languages: English / Japanese / Simplified and Traditional Chinese / Korean / Vietnamese / German / French / Spanish / Italian / Romanian / Czech / Hungarian

Touch Panel Interface For Servo Press

View and analyze process parameters and graphs; comprehensive press control at your fingertips.

For more information, please visit our Catalog & Diagram Download Page or contact us directly.

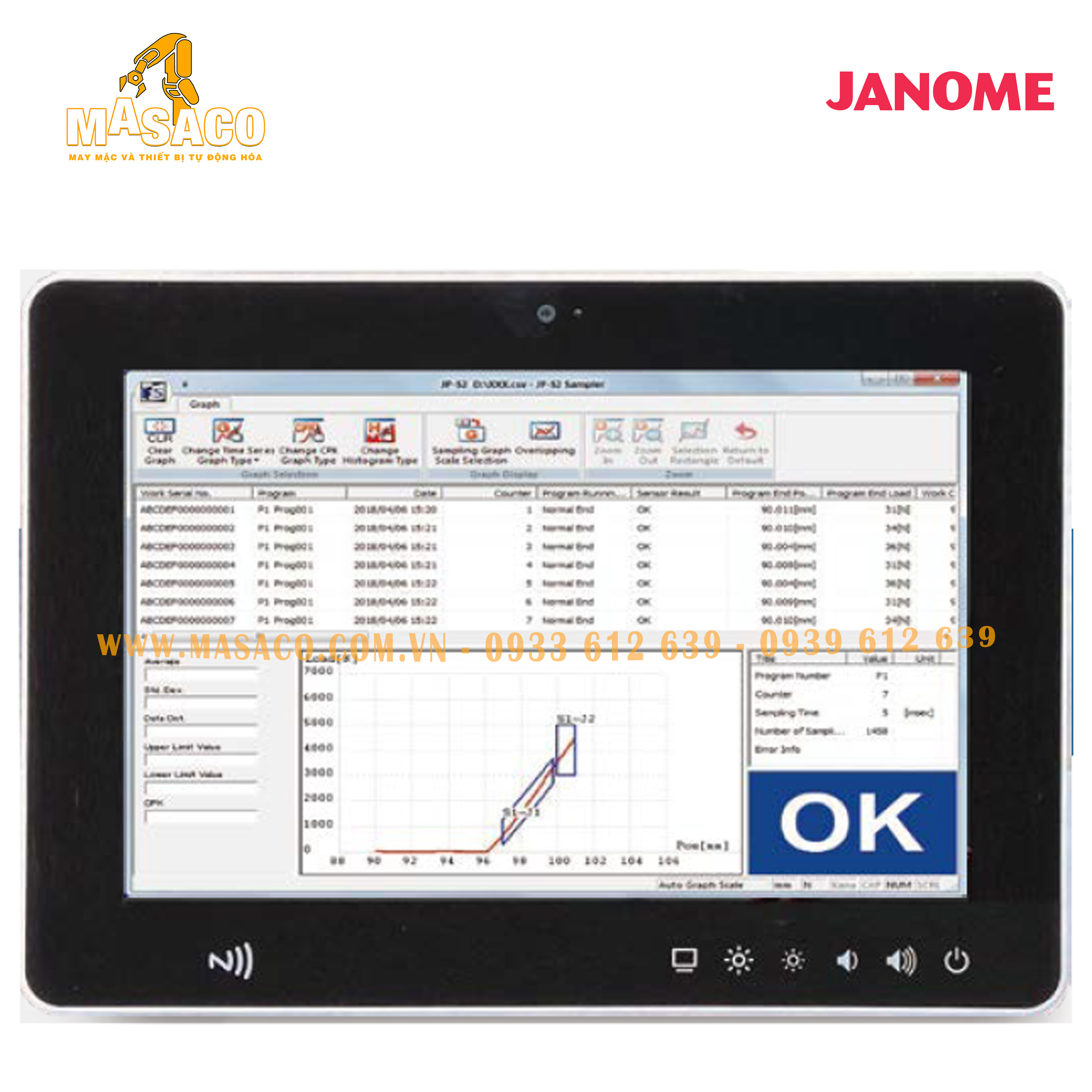

PC Software: TaS Ⅱ System

Compatible with desktop, laptop and HMI (touch panel) PCs; choose the PC setup suitable for your facility.

JP5 Designer

Create, edit, send and receive teaching data

- Upload teaching data from the Electro Press to your PC.

- Create and edit teaching data and send it to the Electro Press.

- Save teaching data on your PC and print it out.

- Acquire time series data via JP5 Sampler and display it as a graph.

- Edit sensor conditions, etc. based upon graphic displays.

- Real time I/O monitoring during press operation.

JP5 Sampler (optional)

Receive and save run result data

- Upload run result data to your PC (minimum sampling interval 0.25msec).

- Display quality control data in list display format, and time series data as a graph.

- Output sampling data in CSV/TXT file format.

- Collect run result data from multiple presses.

JP5 Reporter (optional)

Analyze run results and make reports

- Use quality control data to calculate and display statistical averages and standard deviations.

- Display the frequency distribution (histograms) for end load values and end positions.

- Display CPK (process capability index) data based upon run result data.

- Display operational status program by program.

(Error rate, no. of OK/NOK, average cycle time, average

prep time, etc.) - Make reports in HTML format.

Reviews

There are no reviews yet.